80 - 220BPH Semi Automatic 3-5 Gallon PET Bottle Blowing Molding Machine ( 10-25L Bottle )

The semi-automatic bottle blowing machine is mainly used for the blowing of small-volume plastic bottles.

The semi-automatic bottle blowing machine has the characteristics of energy saving, small area, low investment, fast effect and reasonable structure. It is widely used in packaging products such as food, medicine, cosmetics, pesticides, chemical reagents and soft drinks.

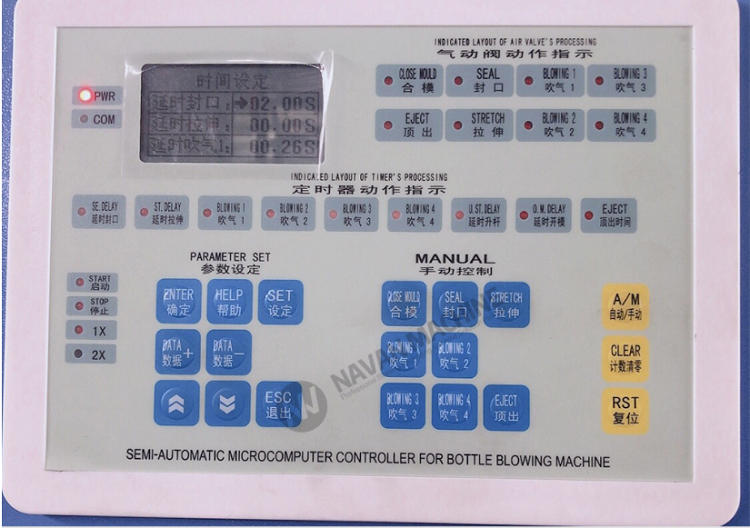

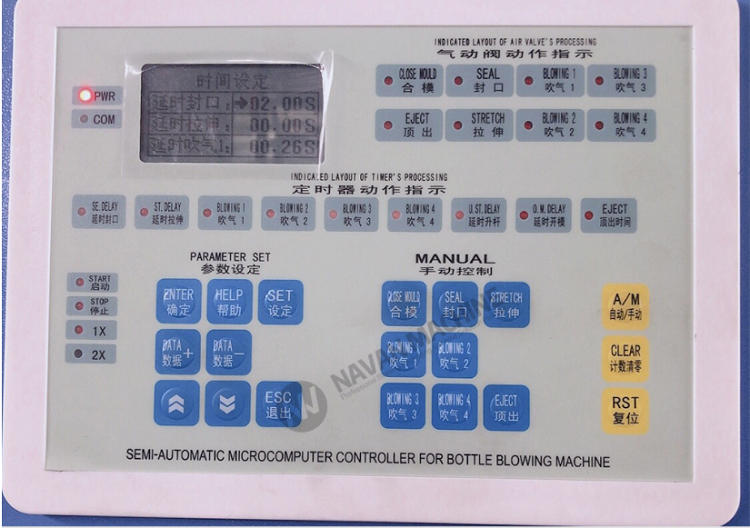

Features of semi-automatic bottle blowing: The host is equipped with a microcomputer program controller, which is easy to operate. The heater adopts imported SCR to control the far-infrared heating tube. The transmission part adopts a three-phase motor and is driven by a frequency converter. The stretching part of the seal adopts the left and right cylinders to stretch the length by one step. The delay time of blow molding can be adjusted freely, which is conducive to product molding. The exhaust gas inside the machine is discharged through the muffler to reduce noise. The host is equipped with gas storage tanks and high and low pressure relief valves.

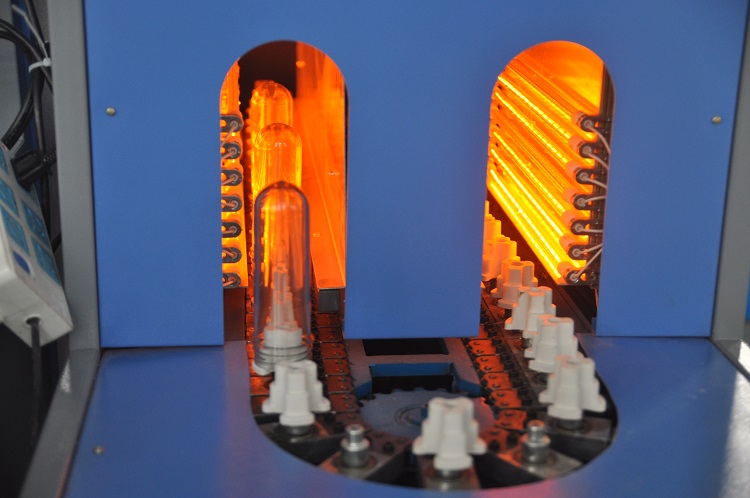

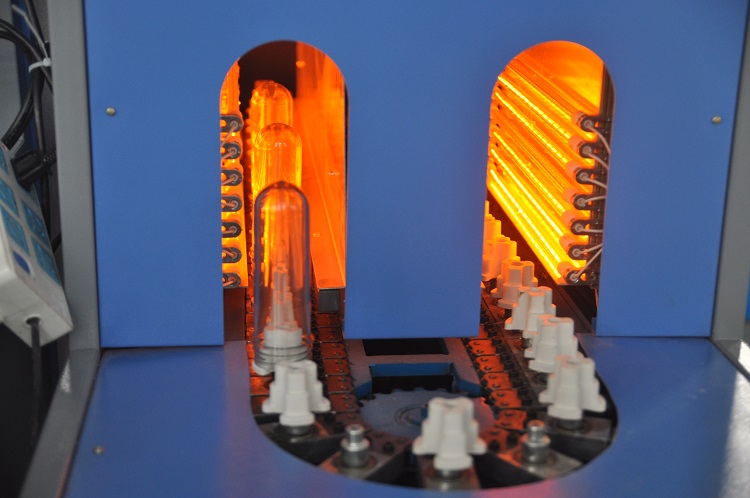

New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

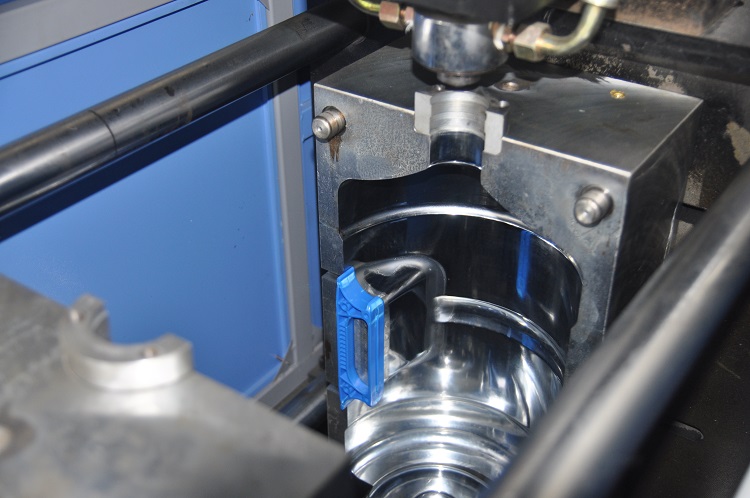

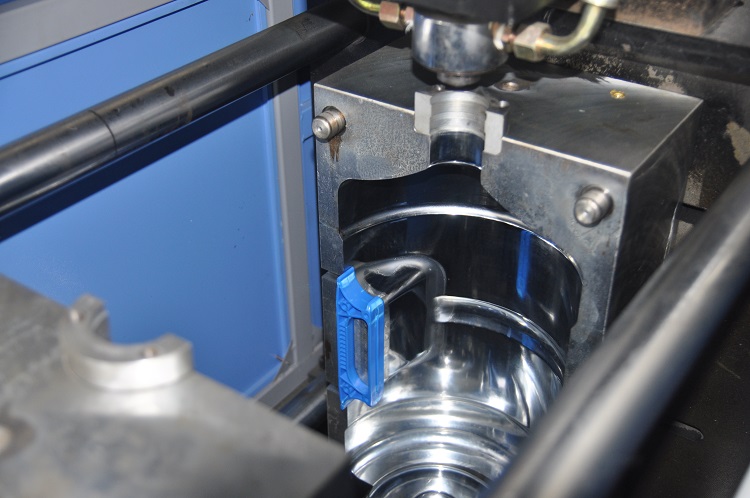

Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottle neck diameter.

Intelligent Human-Machine Interface.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details