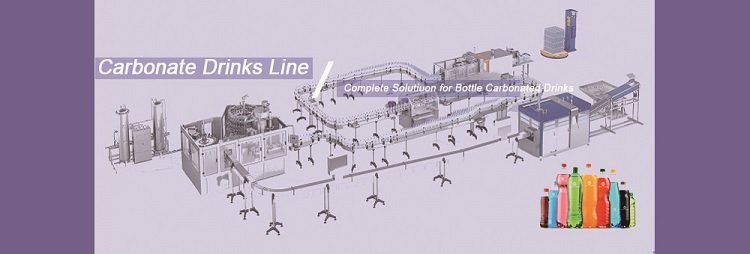

Automatic Carbonated Soft Drink Filling Machine For Soda Water Bottling Line

The machine is suitable for filling and sealing of carbonated drink , craft beer and beverage in the industrial of PET bottle, PLA bottle , Glass bottle beverage field. The filling and seaming are of integral design. The principle of equal pressure filing is adopted.

During filing, after the empty bottle reaches into the bottle lifting cylinder after passing through the pneumatic triplex parts, and the empty bottle is raised and the conical seal gasket under the filling valve is sealed. The position turning block of the filling valve turns the position and opens the valve under the action of another cylinder. The air is filled into the empty bottle to form equal pressure. From a large material barrel, the beer passes through small conduits and flows into the empty bottle. When the liquid level in the empty bottle blocks the gas return pipe mouth, then the filling stops. Under the action of arm, the de-foaming valve will slowly discharge the air and pressure, the can supporting cylinder will continue to fall. After it is discharged, the bottle is sent to the sealing machine for sealing by the hook chain that runs synchronously.

During the sealing, the sealing wheel carries out pre-sealing and then real sealing. After it is sealed, the bottle is pushed out by the beating head of the cap beating mechanism and then dialed by dial to the conveyor belt for conveying.

Product Description

Washing Parts.

The rotary rinsing turret is equipped with a sophisticated system that includes stationary nozzles and gripping mechanisms. These grippers securely seize the bottles as they are propelled by the inlet star-wheel, ensuring a firm and secure hold. Subsequently, the bottle is inverted and positioned above a high-precision spraying nozzle, from which a controlled and precise flow of rinse water is directed into the bottle. Following a designated period for draining, the bottle is then carefully returned to its original upright position.

Filling Parts.

The star-wheels propel the bottles consistently "by their necks" throughout the rinsing, filling, and capping processes. Our specialized design allows for easy adjustment of the structure to accommodate different bottle types by the operator.The purpose of the product bowl is to minimize heat loss.In the event that the temperature falls below the set value, the filling valves will cease operation and the remaining beverage in the filling valve will be returned to the recycle tank. It will then be pumped back to the UHT system for sterilization once again.

Capping Parts.

The rotary capping turret is designed specifically for screwing plastic caps onto PET bottles.The stationary component comprises of the cap hopper, cap feeder with its respective motor, and the cam that operates the capping heads.The heads are elevated and lowered through the movement of a follower that rides along a contoured cam.

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details