Automatic PET Bottle Shrink Sleeve Label Applicators Labeling Machine & Shrink Tunnel

1.Suitable for various bottle types of juice, tea beverage, dairy products, purified water, condiments, beer, sports drinks and other food and beverage industries. Not only does the sleeve label position have high accuracy, but it also highlights the bottle shape after shrinking.

2. Highly stable mechanical structure: The whole machine adopts stainless steel protective frame cover and aluminum alloy rigid frame, which is stable and does not rust.

3. Flexible choice of multiple bottle types: round bottles, square bottles, oval bottles, etc. can be set, and the mouth or body of the bottle can also be selected.

4. Unique synchronous cutter seat, within the specification range, no need to change the cutter seat. If you need to change the specifications, it can be completed quickly in 5 minutes.

5. Wide range of application: suitable for all kinds of plastic bottles, glass bottles, PVC, PET, PS, iron cans and other containers such as food, beverages, cleaning supplies, medicines, wine bottles, etc.

6. High-quality positioning accuracy: Fully mechanical transmission design, using forced sleeve labeling, all kinds of film materials above 0.030MM film thickness are applicable, the film material inner diameter can be adjusted in the range of 5-10.

7. Low maintenance cost of consumables: This machine adopts low-cost disposable blades, which are easy to replace and low cost burden.

Sleeve Labeling Machine - Main Machine.

Machine group: The whole machine adopts a stainless steel body to support the main machine and fix the conveyor belt.

Sleeve Labeling Machine - Shrinking Furnace.

Use electric heat or steam heat to shrink and evenly attach the label to the bottle.

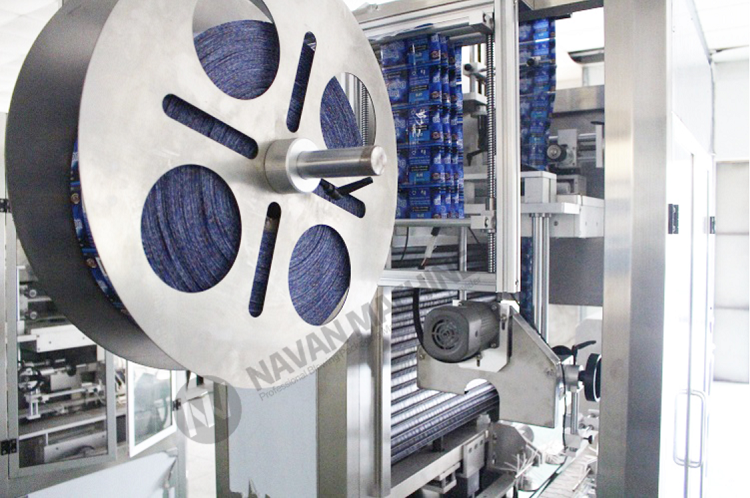

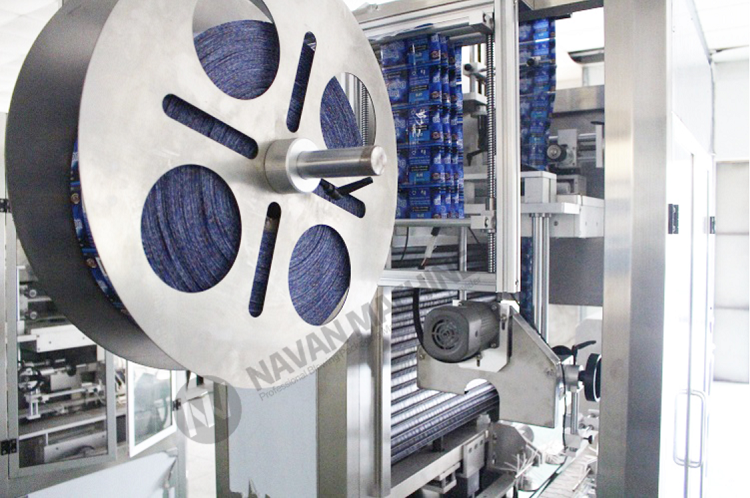

Material rack group:

Save the time of changing materials, the discharge is fed by a set of conveying roller reduction motors.

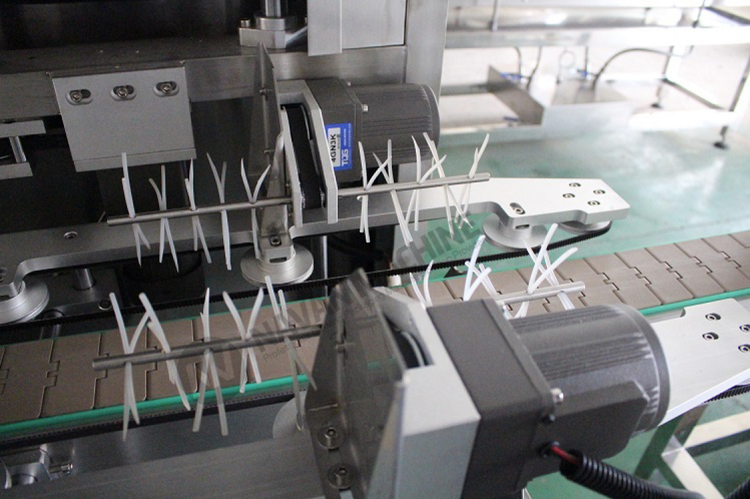

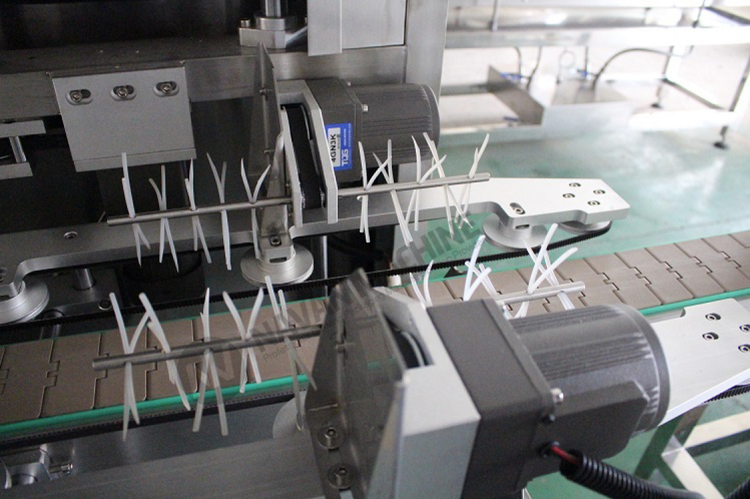

Bottle-separating screw:

Separate the bottles to be set at equal intervals and enter the bottle group.

Cutter set:

It adopts an eccentric linkage mechanism and is driven by a stepping motor. There is no rotation under the induction of no incoming bottles, which increases the service life and safety. At the same time, its cutter adopts ordinary paper cutting blades to replace easily and economically.

Center column: The label film material is sleeved and opened, so that the film material can be conveyed and cut.

Brush set:

Use a strap or rubber band to drive the bottle label brush into position.

Brush-down group:

Using a synchronous adjustment mechanism, adjust the brush-down two sets of transfer wheels to slightly touch the rollers under the center column. When the label passes, the label is inserted into the bottle at a higher speed.

Man-machine interface:

The control center of this machine, each operation display page is divided into main table, manual, automatic, setting, monitoring, etc., and several auxiliary knobs and buttons are used to operate and control sleeve label operations.

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details