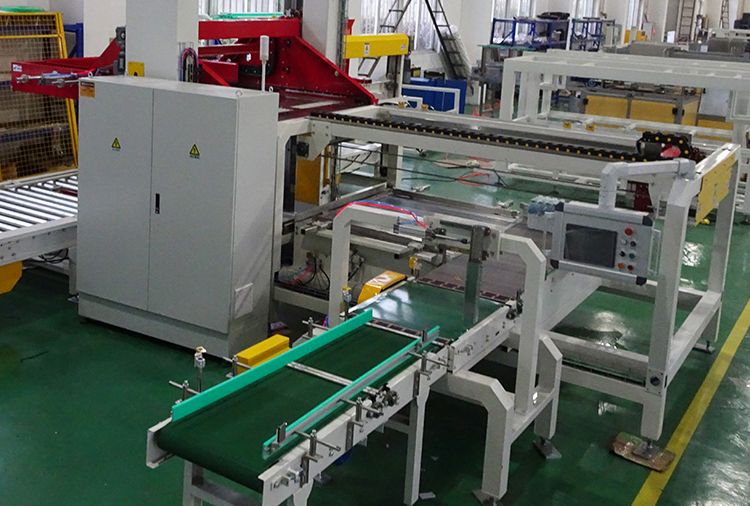

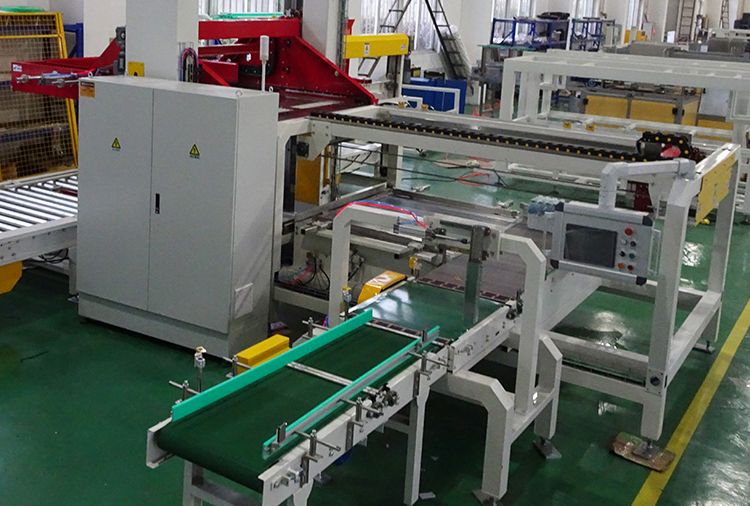

Automatic Palletizer Machine for Stacking Water Bottle Cartons And Palletizing Film Packs on Pallet

The Automatic Palletizer Machine, offered by NAVAN MACHINE, is a cutting-edge solution designed to streamline and optimize your palletizing process. This advanced machine is specifically engineered to automate the stacking and arrangement of products onto pallets, ensuring efficient and precise palletization.

With its state-of-the-art technology and intelligent programming, the Automatic Palletizer Machine can handle a wide range of products and pallet sizes. It offers a high degree of flexibility, allowing you to customize the palletizing patterns according to your specific requirements. Whether you need to stack boxes, cartons, bags, or other items, this machine can handle the task effortlessly.

Featuring a user-friendly interface, the Automatic Palletizer Machine is easy to operate and offers seamless integration into your existing production line. It employs advanced sensors and precision controls to ensure accurate positioning and gentle handling of products during the palletization process, minimizing the risk of damage.

One of the key advantages of this machine is its exceptional speed and efficiency. It can swiftly process large volumes of products, significantly reducing manual labor and increasing productivity. By automating the palletizing process, you can save time, reduce costs, and improve overall operational efficiency.

Furthermore, the Automatic Palletizer Machine is built with durability and reliability in mind. Constructed with high-quality materials, it is designed to withstand the demands of continuous operation in a production environment. This ensures long-term performance and minimal downtime, maximizing your return on investment.

According to a certain order, palletizer stacks the packed products(in box, bag, bucket) to the corresponding empty pallets through a series of mechanical actions so as to facilitate handling and transporting batches of products to improve production efficiency. Meanwhile it can use stack layer pad to improve the stability of each stack layer. Various forms designed to meet different palletizing requirements.

Electrical Configuration:

PLC | Siemens |

Frequency Converter | Danfoss |

Photoelectricity Inductor | SICK |

Driving Motor | SEW |

Pneumatic Components | FESTO |

LOW-voltage Apparatus | Schneider |

Touch Screen | Schneider |

| Servo | Panasonic |

Technical Parameter: Stack Speed | 40 cartons per minute, 4-5 layers per min |

Height of Carton case | >100mm |

Max. carrying capacity /layer | 150Kg |

Max. carrying capacity /pallet | Max 1500kG |

Max. stack height | 1800mm |

Installation Power | 15.3KW |

Air Pressure | ≥0.6MPa |

Power | 380V.50Hz , three-phase four-wire |

Consumption of the Air | 600L/Min |

Size of the Pallet | According to customer reqirement |

After Sales Protection:

1. Ensure outstanding quality

2. Professional engineers with more than 7 years experience, all in readiness

3. Available on-site installation and debugging

4. Experienced foreign trade staff to guarantee instant and efficient communication

5. Provide lifelong technical support

6. Provide operation training if necessary

7. Quick response and in-time installation

8. Provide professional OEM&ODM service

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

Pусский

Pусский Français

Français 简体中文

简体中文

Products Details

Products Details