The bottled water production line is applicable to the production of 350ml, 500ml, 1L, 1.5L bottled purified water, mountain spring water, mineral water and other products, such as Wahaha, Yibao, Evergrande ice spring and other well-known brands on the market. At present, the equipment output of the bottled water production line provided by the company can reach 2000 bottles per hour ~ 36000 bottles per hour (calculated on the basis of 500ml PET bottles).

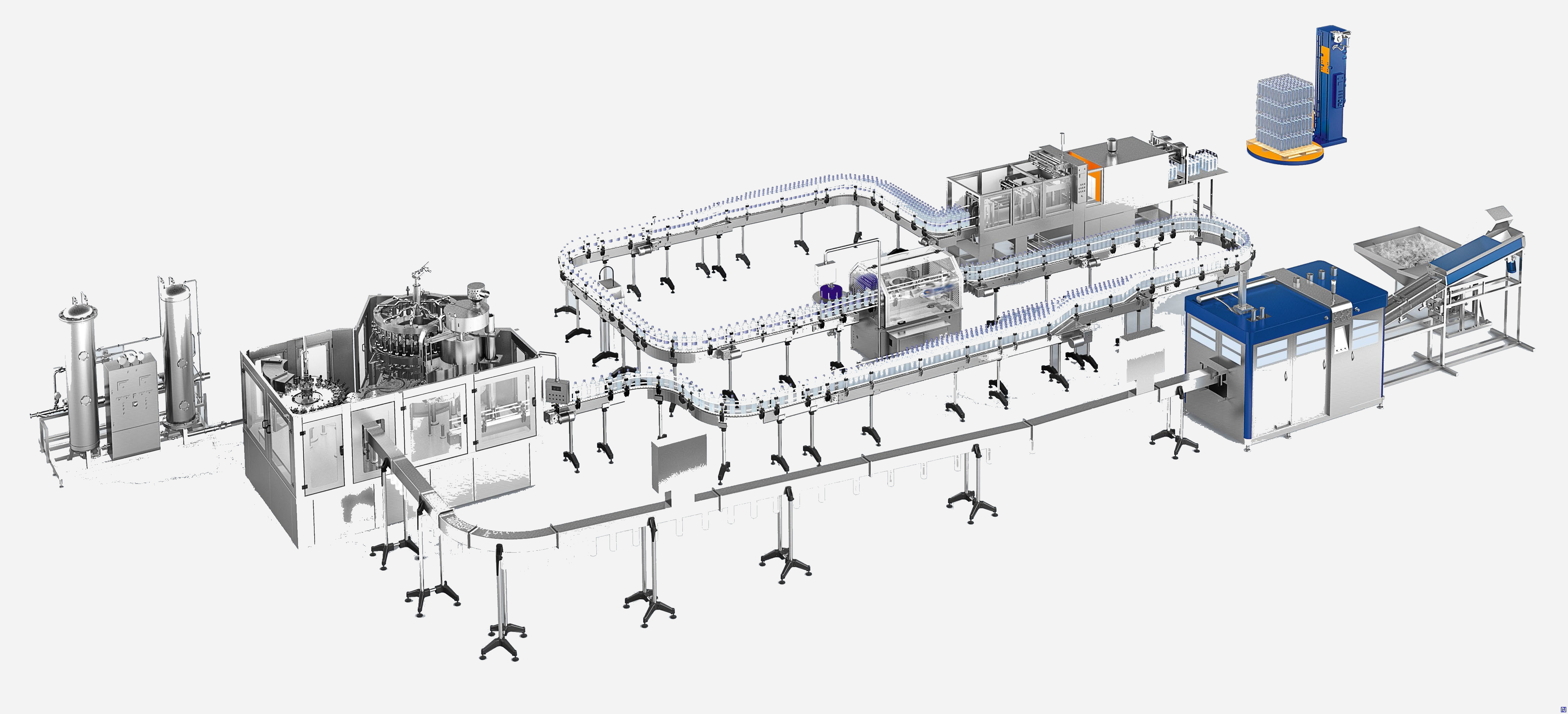

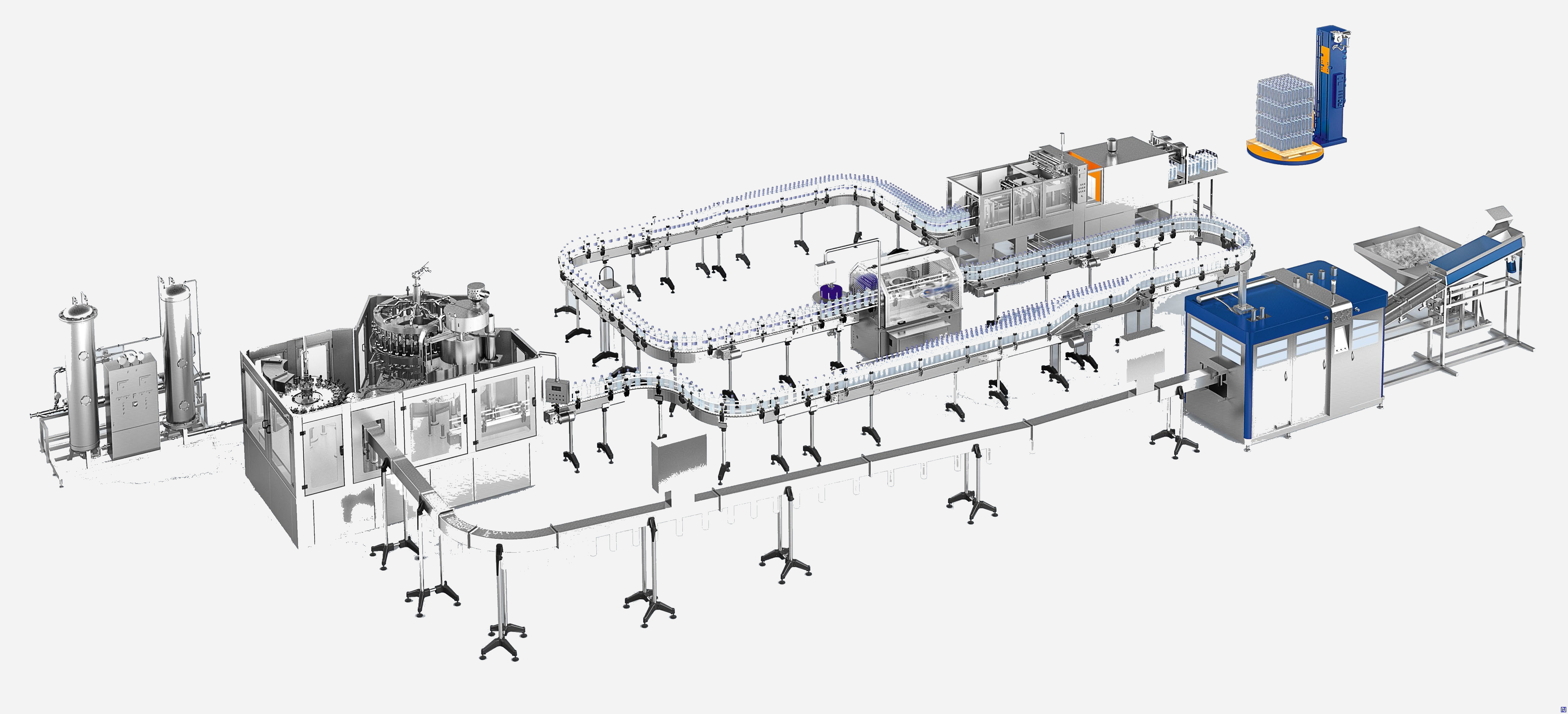

The equipment of bottled water production line is mainly composed of water treatment system, bottle blowing system, filling system and packaging system.

The water treatment system is equipped as follows:

Water sources generally come from groundwater, mountain spring water, urban tap water, etc. bottled water manufacturers need to take the existing water samples to relevant departments for testing. We will check and evaluate the water analysis report, work out a set of detailed water treatment scheme, and select corresponding water treatment equipment to make the finished water meet the drinking water standard.

The pre-treatment equipment for purified water, mountain spring water and mineral water is basically the same, mainly including the following products:

Quartz sand filter: used to remove particle impurities in source water and reduce SDI (pollution density index) value of source water.

Activated carbon filter: used to adsorb organic impurities and molecular colloidal micro particle impurities in source water, remove color and odor, and also used for dechlorination.

Sodium ion exchanger: the calcium and magnesium ions constituting the hardness of the source water are removed through the sodium ion exchange resin in the softener, so that carbonate scale is not easy to form in the water, so as to soften the source water.

Precision filter: it can filter out most particles and bacteria and protect the back hollow fiber ultra-filtration membrane or RO reverse osmosis membrane.

The above are coarse filtration equipment, which can protect the subsequent core membrane elements. RO reverse osmosis shall be selected for the production of purified water. Primary or secondary reverse osmosis equipment shall be selected according to the conductivity of source water and relevant technical parameters. Hollow ultra-filtration or nano-filtration equipment shall be used for the production of mountain spring water and mineral water. The details are as follows:

RO reverse osmosis: the solvent in the solution is separated through reverse osmosis membrane to remove micro particles, organic matter, bacteria, viruses, etc. the desalination rate can reach 99.7%, making the source water pure water.

Hollow fiber filter: commonly known as ultra-filtration, it mainly removes bacteria and particles in the source water and retains minerals beneficial to human body in the source water.

Ozone mixing tower: fully mix the filtered water with ozone, use the strong oxidation of ozone to achieve the effect of sterilization, control the time and concentration, and ozone can kill all kinds of bacteria. In the production of mountain spring water and mineral water, ozone sterilization can not lose and affect the beneficial elements in mineral water.

Titanium rod filter: it is mainly used to filter the bacterial bodies left in the process of ozone sterilization.

Then, the sterile purified water, mountain spring water or mineral water is pumped into the sterile water storage tank for storage, and the finished product flows to the bottled water filling equipment through the connecting pipe for bottle washing and filling.

The bottle blowing system is equipped with the following:

Bottle blowing equipment: it is mainly used to blow the bottle PET preforms to a bottle. Firstly, the bottle PET Preform enters the oven for heating, and the heat source is provided through the lamp tube. During the heating process, the bottle PET preform rotates and rotates to ensure that the surface of the preform is evenly heated. After entering the bottle mold, the bottle preform is blown into a bottle through filtered high-pressure gas.

The filling system is equipped with the following:

Filling equipment: commonly known as 3 in 1 filling machine in the industry, the equipment matched with the 3 in 1 filling equipment include: full-automatic bottle unscrambler machine, automatic capping unscrambler machine and online bottle cap disinfection machine. When the production output of bottled water is large, it can be equipped with a full-automatic bottle feeding machine to connect the bottle unscrambler machine with the 3 in 1 filling machine through the air conveyor. Through the automatic bottle feeding machine, the disordered bottles are sent into the bottle unscrambler machine to make the bottles arranged in a straight line after straightening, and then enter the bottle inlet air convetor in turn. Under the action of wind, they enter the 3 in 1 filling equipment to rinsing, filling and capping.

When the production output of bottled water is small, the semi-automatic bottle loading platform can be selected for manual bottle loading. For bottle cap disinfection, we adopt the on-line bottle cap disinfection method instead of the traditional bottle cap disinfection cabinet. The bottle caps are sent to the capping device through the automatic capping machine. After straightening out in order, the bottle caps enter the bottle cap disinfection tunnel in turn. Through the internal wind system, the bottle caps move forward slowly, disinfect, rinse and drain in turn, and enter the capping device through the slide, Cap the filled bottle. It should be noted that the 3 in 1 filling equipment should be in the sterile room for production to avoid the entry of particles, impurities and bacteria during the production of bottled water, so as to ensure the safety of each bottle of water.

The packaging system is equipped with the following:

Packaging equipment: the semi-finished products after capping pass through light inspection equipment (manual visual inspection of impurities in the bottle), code spraying equipment (including ink code spraying machine and laser code spraying machine, which are used to print the current production date on the bottle body), label equipment (including labeling machine, single-sided labeling machine, double-sided labeling machine, rotary labeling machine,hot glue sticker labeling machine and shrink sleeve labeling machine, which are used to install labels on the bottle body) Packaging equipment (including film packaging machine and carton packaging machine, randomly combine scattered bottled water into 24 bottles / box, 12 bottles / box and 20 bottles / box). When large-scale production is achieved, robot stacker can be selected to automatically stack bottled water products instead of manual handling, so that the whole bottled water filling production line can be fully automated.

NAVAN PET Bottled Mineral Water Production Line

Navan Industrial has invested its best resources in technical research, to design and realize innovative in bottle blowing, filling, capping , labeling and packing systems which enable to respond and reach different demands and achieve new goals everyday, seizing the market's expectations in the pass years .At the same time , we also provides turn-key services for customers, from plant layout, equipment manufacturing, production line setup, to operators training. We are always trying our best to meet the demands of our customers continuously and seeking for mutual development.Today Navan has enhanced its exsitence both in domestic and global market. Thanks to its various and perfect cases, we provide our customers with delicated and customized solutions at quick response. Navan machines are utilized in large and small companies all around the world since 1990s.Massive experience gained through the years of water, juice , soft drink , beer, honeys, sauces etc., with all the abundant experience we are able to deal with any problems related to specific customers requirements, such as daily or special products., and perfect the creation of various machine to satisfy any customer's demands.

What should we pay attention to when choosing mineral water filling production line?

The production line of mineral water filling equipment has a wide range of applications and high market sales, Therefore, understanding what matters should be paid attention to when choosing mineral water filling production line is the way to help consumers buy high-quality equipment.

1. Manufacturer's plant area, production capacity and other hardware facilities

Due to the complex manufacturing process of mineral water equipment, a certain plant area is required as support. Some enterprises spread information everywhere after registering a company casually. In fact, there is no plant. After receiving the order, they can only find someone to do OEM. Although the equipment made in this way is cheap, the quality is unreliable. Therefore, when selecting manufacturers, you should go to the company for onsite investigation. Of course, it would be better if you have a friend in the industry to introduce the designated manufacturer. The quality of such manufacturer is absolutely excellent.

2. Manufacturer's after-sales service

After sales service is an important part of selecting manufacturers. The production of mineral water equipment cannot be done once and for all. After using the equipment for a period of time, problems may occur due to aging and other reasons. At this time, it depends on the manufacturer's after-sales service. Although some large companies have high brand awareness, but their after-sales service is really poor. There is only one reason: the profit of after-sales service is too low and people have no willing to do it. Generally speaking, mineral water equipment is guaranteed for one year, after-sales door-to-door, and relevant operation instructions and basic knowledge such as how to maintain and regenerate will be informed during on-site installation. When investigating the manufacturer's after-sales service, a convenient way is to ask the relevant customers of the manufacturer and listen to their evaluation of the manufacturer.

3. Appearance and main accessories of equipment

Whether the appearance of the equipment is exquisite or not can largely see the meticulous degree of the manufacturer's manufacturing process. Generally speaking, it mainly focuses on the following points: the overall beauty of the equipment, the uniformity of pipeline lines, the flatness of frame welding, and the strength and durability of stainless steel.

For the main accessories, it should be emphasized that the water quality of mineral water equipment mainly depends on the quality of membrane, resin, activated carbon, pump and other materials. Generally speaking, American hydergic membrane, American Rohm Haas resin, coconut shell carbon and Southern pump are well-known brands in the industry, to make sure the quality of the equipment, NAVAN has been insisting on the use of brand quality products and accessories since the early days of the company's establishment, in order to ensure product quality and good products can also improve productivity. Therefore, when you select a manufacturer, you must ask about the brand of its relevant main accessories. In addition, you also need to carefully check these main accessories during on-site installation, record the model of main accessories, and check their authenticity online, so as to prevent some manufacturers from shoddy goods and profit from them.

4. Understand their own source water quality and required equipment configuration

When selecting mineral water equipment, you should first have a general understanding of your own water quality and required water consumption, so as to select matching mineral water equipment. NAVAN normally will ask for your Water Analysis Report to evaluate and choose a scientific water treatment solution for your plant,. There is only one purpose: to buy the right equipment with the right money and reduce costs. In order to make profits, some bad manufacturers blindly encourage customers to buy high configuration equipment at a high price without considering its applicability and efficiency. Therefore, when making a choice, you should check as much information as possible and ask more professionals first to know well.

简体中文

简体中文

News Detail

News Detail