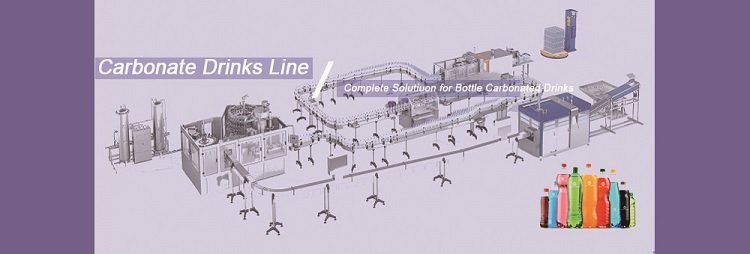

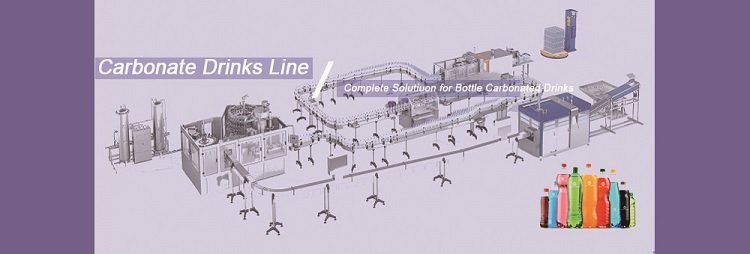

Carbonated Soft Drink Filling Line Automatic Full Set Soda Water Bottling Line

The machine is designed for filling and sealing carbonated drinks, craft beer, and other beverages in PET bottles, PLA bottles, and glass bottles in the beverage industry. The filling and sealing processes are integrated into one design, and the principle of equal pressure filling is used.

During the filling process, the empty bottle is guided into the bottle lifting cylinder through the pneumatic triplex parts. The bottle is then lifted, and the conical seal gasket under the filling valve seals the bottle. The filling valve's position turning block turns and opens the valve with the help of another cylinder. Air is injected into the bottle to create equal pressure. The beverage flows from a large material barrel through small conduits and fills the bottle. Once the liquid level in the bottle reaches the gas return pipe mouth, the filling process stops. The de-foaming valve slowly releases the air and pressure under the action of an arm. The bottle is then lowered by the can supporting cylinder. After the filling is complete, the bottle is sent to the sealing machine for sealing using a hook chain that runs in sync.

During the sealing process, the sealing wheel performs pre-sealing and then final sealing. Once sealed, the bottle is pushed out by the cap beating mechanism and transferred to the conveyor belt through a dial for further transportation.

Product Description

Washing Parts.

-The rotary rinsing turret is equipped with fixed nozzles and grippers for bottle handling.

-The grippers securely grasp the bottles while they are still being driven by the inlet star-wheel, ensuring a safe grip.

-Once gripped, the bottle is inverted and positioned above a spraying nozzle, which directs a stream of rinse water into the bottle.

-After the draining period, the bottle is returned to an upright position.

Filling Parts.

-Our specialized design allows the star-wheels to drive the bottles by the neck during the rinsing, filling, and capping processes, making it easy for operators to adjust the structure for different types of bottles.

-The product bowl is designed to minimize heat loss.

-If the temperature falls below the set value, the filling valves will stop and the last beverage in the filling valve will be returned to the recycle tank. It will then be pumped back to the UHT system for sterilization.

Capping Parts.

-Rotary capping turret, suitable to the application of screw plastic caps on PET bottles

-The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads.

-The heads are raised and lowered by the action of a follower that is riding on a shaped cam

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details