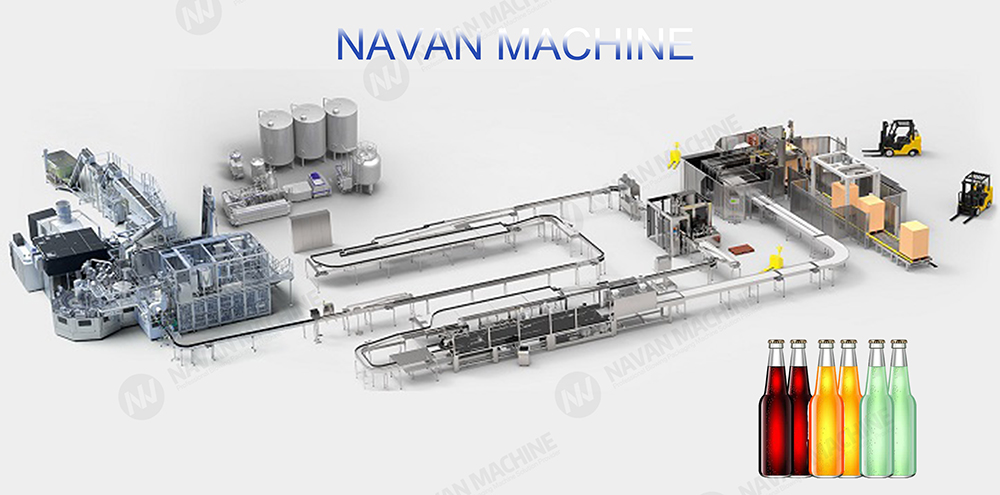

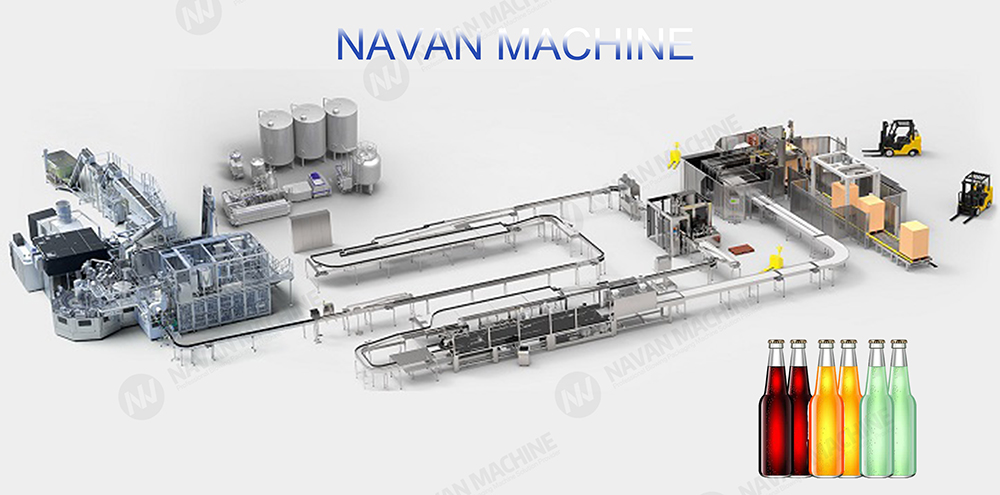

Full Automatic Glass Bottle Beer Washing Filling Capping Machine Craft Beer Filling Line

The glass bottle filler and capper offered here has been developed by incorporating and enhancing advanced technology from around the world, ensuring it meets international standards. This series of machines is versatile and can accommodate various sealing methods such as capper, T-cork, wooden cork capper, and screw capper. It is suitable for filling and sealing water, carbonated soft drinks, fruit juice, coffee drinks, protein drinks, beer, rice wine, and more, showcasing its leading domestic technology. The machines feature a popular international design that is both aesthetically pleasing and practical, making them easy to operate and maintain. Additionally, they offer a high level of automation, making them an excellent choice for both new and established factories.

Product Description

1 - Bottle packing solutions to reduce your total cost of ownership

2 - Higher speeds with gentler handling

3 - Hygienic production for top quality water

4 - Reduced consumption with more efficient resources use

Washing Parts.

- The bottles are conveyed directly to the bottle dial through an air conveyor.

- The rinse heads are made of 304/316 stainless steel and designed with a water spray style injection, resulting in reduced water consumption and improved cleanliness.

- The gripper, made of 304/316 stainless steel with a plastic pad, ensures minimal bottle collisions during the washing process.

Filling Parts.

- The filling nozzle of this machine is made of high precision 304/316 stainless steel.

- The filling volume can be adjusted with fine precision, ensuring the same liquid level after filling.

- All contact parts and the liquid tank are made of 304/316 stainless steel, which is finely polished and has no dead corners, making it easy to clean.

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details