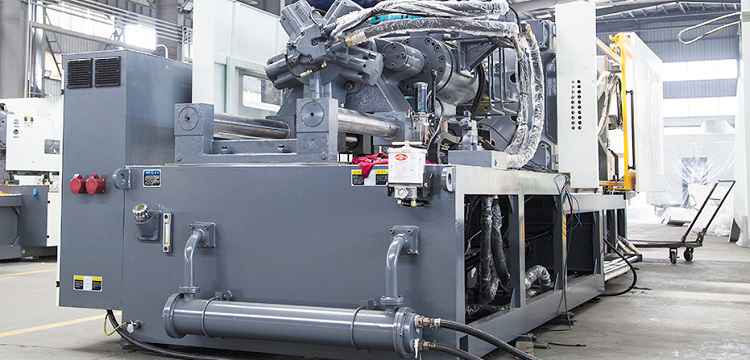

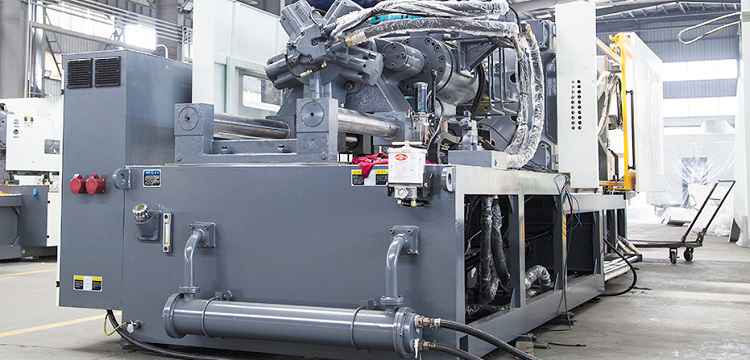

NAVAN Support PET Preform Injection Molding Machine

It is the main molding equipment for making thermoplastic or thermosetting materials into various shapes of plastic products using plastic molding molds.

An injection molding machine is usually composed of an injection system, a clamping system, a hydraulic transmission system, an electrical control system, a lubrication system, a heating and cooling system, and a safety monitoring system.

1.Injection System

The function of the injection system is that in a cycle of the injection molding machine, a certain amount of plastic can be heated and plasticized within a specified time, and the molten plastic can be injected into the mold cavity through a screw under a certain pressure and speed. After the injection, the molten material injected into the cavity is kept in shape.

2.Clamping System

The function of the clamping system is to ensure that the mold is closed, opened and ejected. At the same time, after the mold is closed, sufficient clamping force is supplied to the mold to resist the cavity pressure generated by the molten plastic entering the mold cavity, and to prevent the mold from opening seams, resulting in a bad status of the product.

3.Hydraulic Transmission System.

The function of the hydraulic transmission system is to realize the injection molding machine to provide power according to the various actions required by the process, and to meet the pressure, speed, temperature and other requirements of the various parts of the injection molding machine.

4.PLC Contorl System.

This part is reasonably coordinated with the hydraulic system to realize the process requirements (pressure, temperature, speed, time) and various program actions of the injection machine.

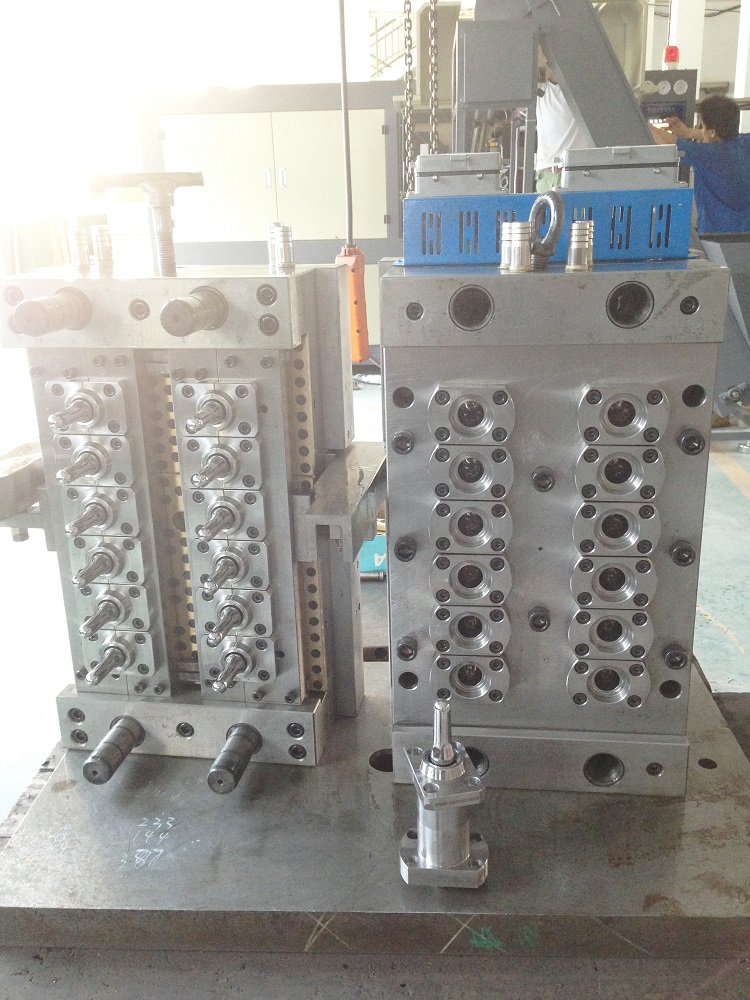

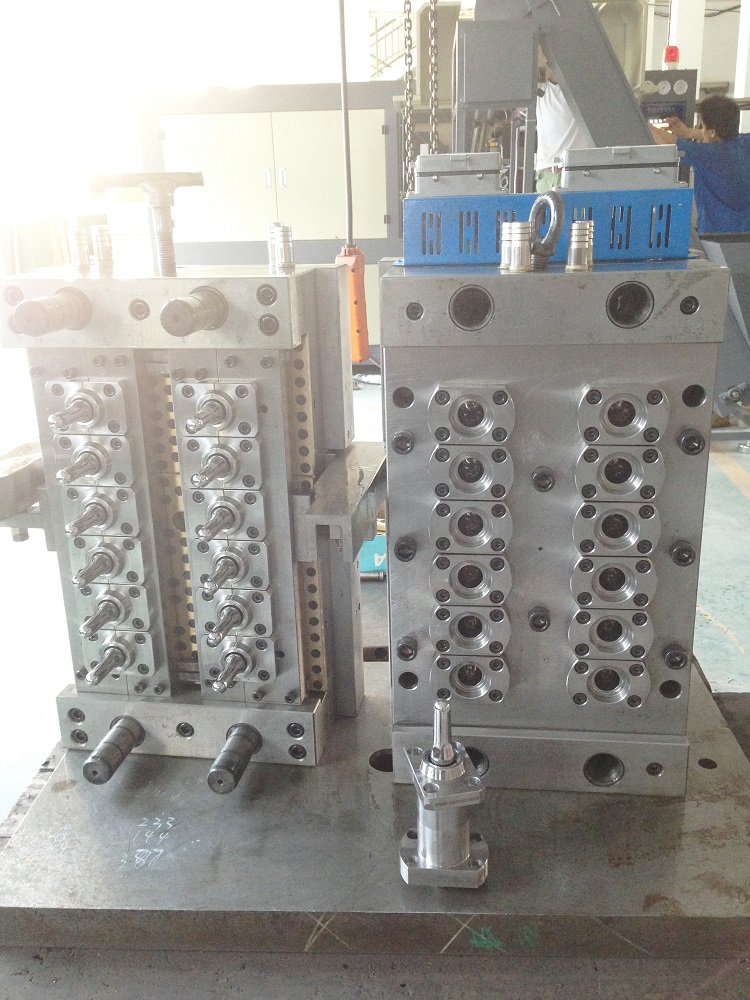

5.PET Preform Mould

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details