NAVAN High Speed Aseptic Drink Bottling Milk Filling Machine

Navan Aseptic cold filling production line consists of the cleaning and sterilization technology, sealing isolation technology, microbial detection and control technology, air purification, filling sealing technology, automation control technology, applied to acidic beverages, neutral non protein drinks and some neutral protein beverage.

Navan advanced equipment can maximize expand beverage filling process capacity and can keep good beverage product nutrients, flavor, color, especially for some thermal sensitivity drinks is better. At the same time , it offers a wide range of space for the diversification of product package design and the saving cost of PET bottle .

Features:

1. The whole machine adopts modular design, each function module combination for all-in-one computer for easy operation

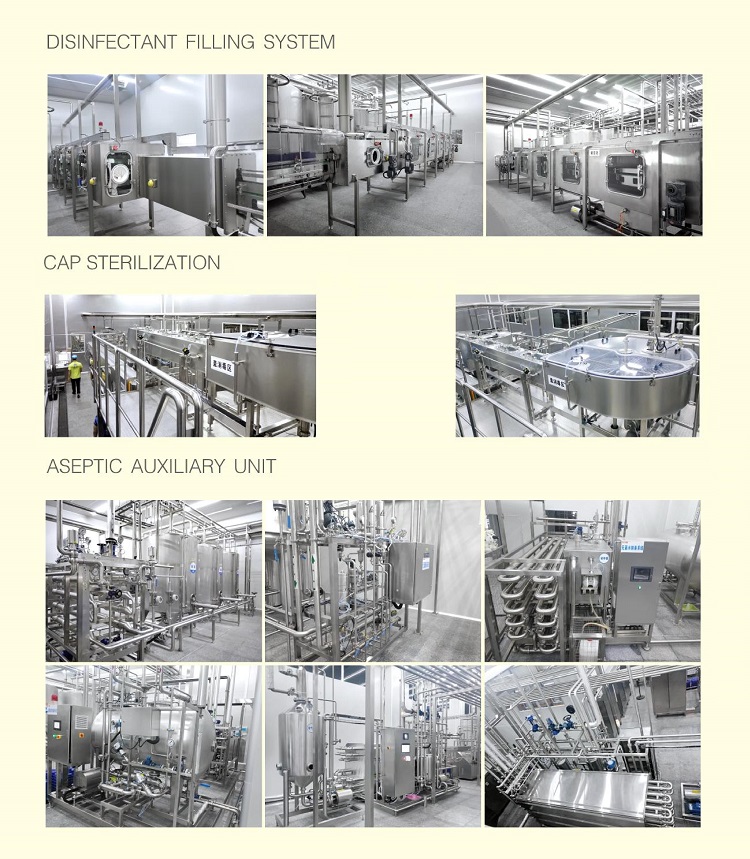

2. The whole machine adopts the isolation cover seal, high efficiency fan and aseptic filtration system to ensure that the internal space of positive pressure, sterile state;

3. Automatic detection, control and record the process of the system, can real time monitor and record the related processes of each link in production line.

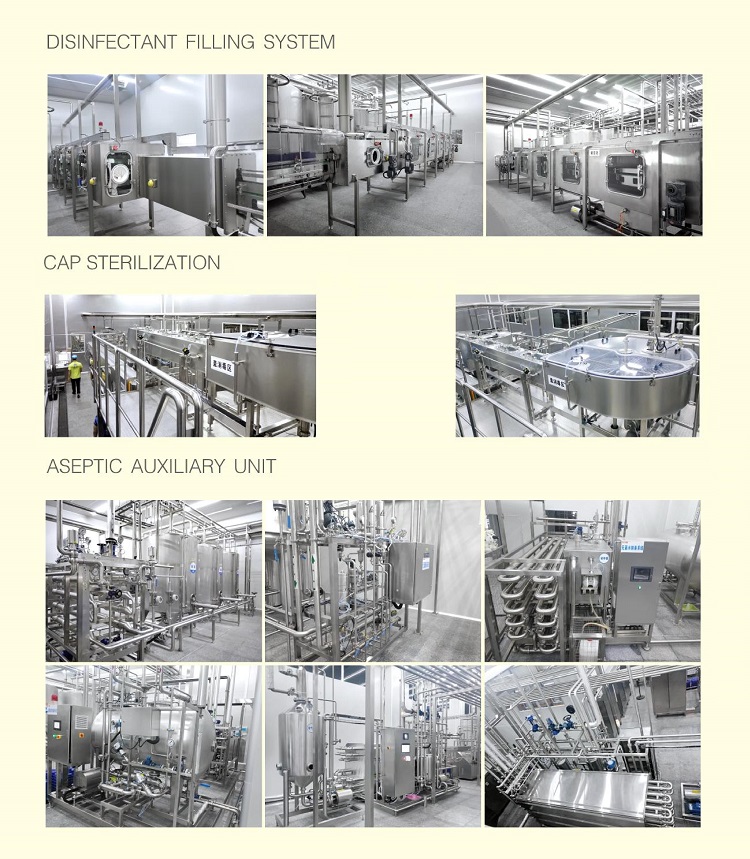

4. Tunnel disinfectant perfusion, keep sterilization, sterilization thoroughly;

5. Imported high efficiency nozzle omni-directional sterile water bottles, effectively guarantee the disinfectant residual standard;

6. Non-contact filling valve, avoid crossing infection and can ensure safety;

7. Electromagnetic induction meter or weighing transducer accurate quantitative filling quantity;

8. Automatic CIP cleaning off cup structure to ensure the efficient, clean and convenient cleaning.

9..Cap by soaking sterilization, tunnel sterile water washing, sterilizing thoroughly.

10. Magnetic closure oral 10. The constant torque, to ensure sealing qualification rate;

11. The sealing transmission part USES the steam heat shield technology, effectively guarantee the sterile isolation of the region and the contaminated area

12. The moving parts of the machine and rotating mechanism adopts the liquid seal technology, guarantee the sterile area is not contaminated.

13. The whole machine adopts the external lubrication system, safety, convenience, guarantee the lubrication effect of long-term and stable;

14. The machine inside and outside of CIP and SIP, COP, SOP and other cleaning sterilization process adopts fully automatic control, efficient, convenient, fast;

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文

Products Details

Products Details