1 - NAVAN Machine Water Treatment System

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

1/The mat shell is made of stainless steel and can withstand high pressure.

2/The system includes various indicators such as capacity, pressure, and electricity, as well as magnetic valves, balance devices, and pipe valves.

3/An online pressure auto self-protection device is integrated into the system.

4/The system also features an online electricity indicator with stable compensation.

5/A safety protection and alarm system is included to ensure system safety.

6/The system is built on a sturdy frame.

2 - NAVAN Machine Blow Molding Machine

1/The NAVAN Machine Blower boasts industry-leading performance, thanks to its patented control and self-regulation systems that ensure consistently high bottle quality.

2/With the ability to configure up to 200 different equipment sizes from a single platform, our production process offers unparalleled flexibility.

3/Our top-quality electrical stretching technique ensures the integrity of each bottle, while full material distribution control guarantees optimal performance.

4/Enjoy boosted uptime and speed with our fast output, capable of producing up to 2,400 bottles per mould per hour.

5/Our efficient consumption methods help reduce electricity usage by up to 45% and compressed air consumption by up to 35%.

3 - CGF Water Filling Machine [ Washing Filling Capping 3 in 1 type ]

1 / Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

3 / Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4 / Hygiene improvement through volume control and contactless filling

5 / Automatic dummy bottles: Safer, easier cleaning procedures

6 / Automatic bottle changeover improves uptime

| Equipment Type | Automatic |

| Bottle Type | PET round or square bottle Volume 200 - 2000ml Bottle diameter 50-115mm Bottle height 160-320mm |

| Output <bph> | up to 36,000 bph |

| Your product | mineral water/pure water/non-gas wine drink and so on |

| Certificates | CE / SGS / ISO 9001 |

4 - NAVAN Machine Labeling Machine

Boasting four carousel sizes, up to three labelling stations and 24 configurations, can generate outputs of up to 72,000 containers per hour, when standalone, at an efficiency rate of 98%.

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

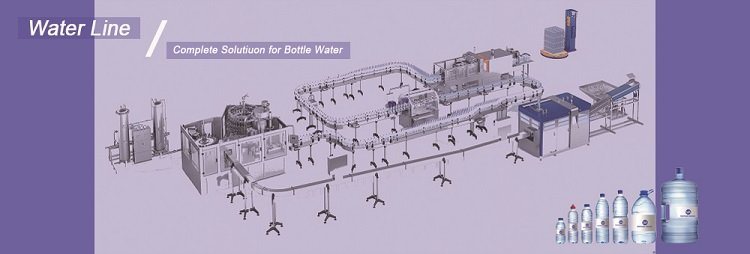

5 - NAVAN Machine Packaging Machine

After filling your drink and labeling the bottle, it is carefully moved by conveyors to the next stage for secondary packaging. This is the package that customers will see when they purchase it, so it must catch their eye. The packaging protects the product from various elements like weather, pressure, and temperature changes. NAVAN Machine packers offer different options like shrink-printed film, nested packs, or wraparound cartons to gently package the bottles, creating long-lasting and affordable packaging.

BENEFITS.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

Automatic Carton Packing Machine with hot melting glue

L Type Film Wrapping Packing Machine

Linear Type Film Wrapping Packing Machine

finished product display

Would like to know more about NAVAN Machine equipments, feel free to send us an inquiry!

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

Pусский

Pусский Français

Français 简体中文

简体中文

Products Details

Products Details