Brief Introduction

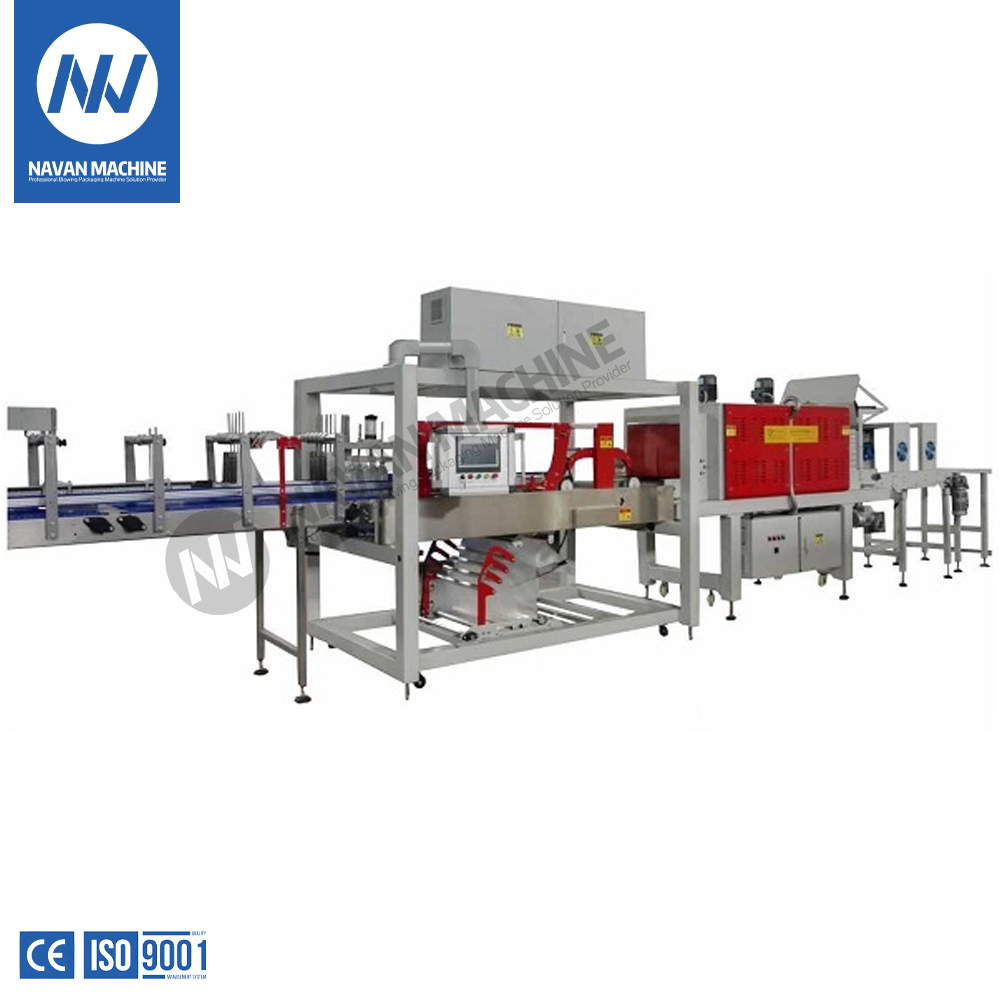

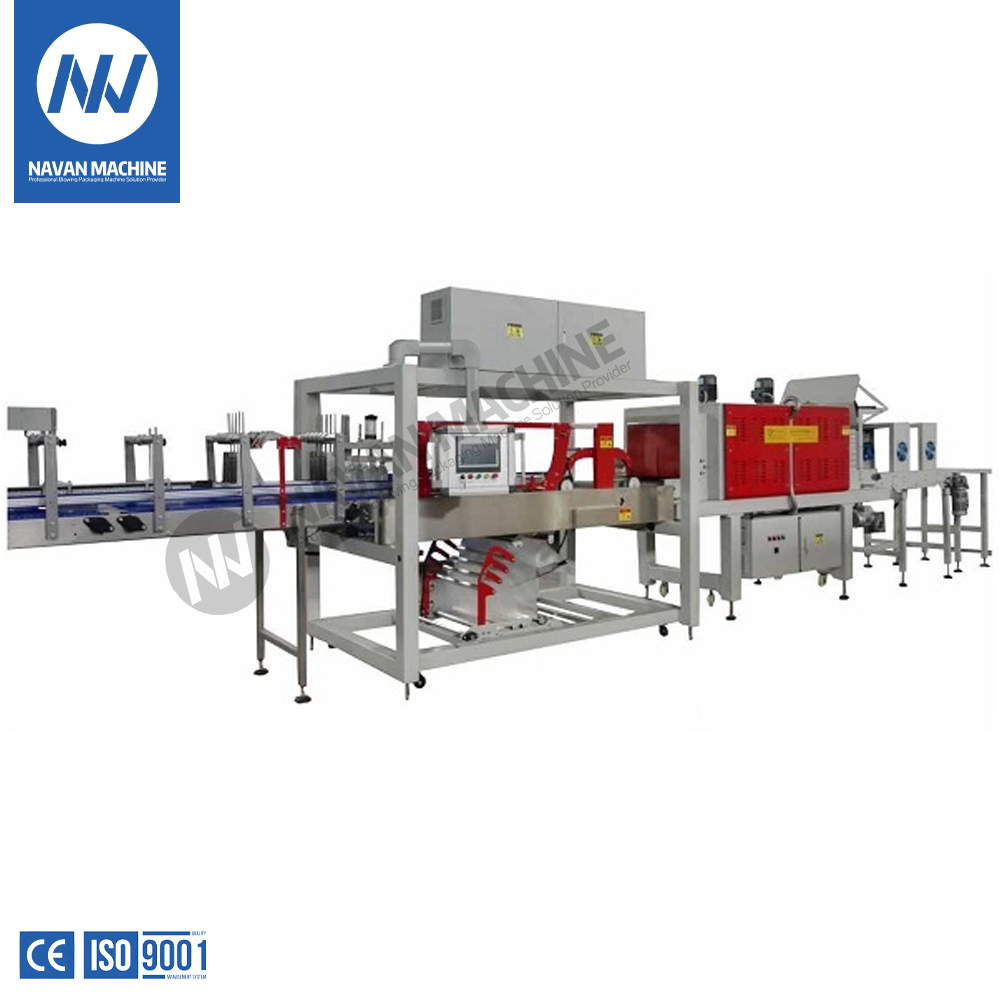

As a newly updated packaging equipment, NV-MBS45 One-piece Heat Shrink Film Wrapping Machine is designed and manufactured with high efficiency and continuous operation based on the characteristics of heat shrinkable packaging film. It can arrange, set up a single product (such as PET bottle), set up a group, push the bottle and wrap the film, and finally form a collection package by heating shrinkage and cooling. The products after packaging are firm, regular and beautiful in appearance and cost saving.

Main Features

1) Specially designed for bundle packing of beer, drinks and beverage, fruit juice, bottle water, dairy, condiment and so on with or without bottom support.

2) Unique film layoff mechanism and constant tension film conveyor are adopted, featuring instantaneous film cutting, automatic film connecting and 4 wrapping and higher strength after shrinking packing.

3) Special shaking setting for bottle-dividing,none status for blocking and bearing bottle,smooth transport

4) Equipped servo motor control system, bottle-feeding, film feeding, film cutting and film wrapping are accurate, synchronous, stable and reliable.

5) The 10-inch LCD color screen has a friendly operation interface,and it is rapid for parameter setting and convenient for human-machine communication, operation and control.

6) Adopting air circulation technology, the shrinkage chamber features rational structure, heat insulation, high precision for temperature control and better packing effects.

7) Ulunn-film transfer system, use ultra-thin PE film with faster speed and stable.

8) More than 90% of electrical components are imported high-quality brands, stable and reliable.

9) The whole machine adopts energy-saving technology design, saving 35% energy consumption, low carbon and environmental protection.

10) The machine can be added print film system, cardboard + film or tray + film packing setting.

Product Specification

1) Packaging Product :380ml/500ml/1000ml/2000ml PET Bottled Water and Tin Canned Beverage (or other special containers)

2) Packaging Specification:2×3, 3×4, 4×6 (or other combinations)

3) Max Package Dimension: 460×280×350 mm

4) With or without cardboard supporting tray

Machine Specification

1) Machine Dimension: 17685×1530×2500 mm

2) Shrinkage Tunnel Dimension: 2500×700×450 mm

3) Packaging Speed:40 Packs/Minute

4) Conveying Belt Width: 610 mm

5) Voltage/Power: 380V /55KW

6) Working Air Pressure: 0.6-0.8 Mpa

7) Air Consumption: 0.3 m3/minute

8) Packaging Form:One piece heat shrink film wrapping

9) Packaging Material : LDP

10) Special solutions for Printed Shrink Film(with designed Logo& company information) Wrapping.

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details