Equipment overview

High CO2 mixer is a new type of mixer developed by ourselves on the basis of introducing foreign technology. With its good performance and precision, the mixing and carbonization system provides you with good conditions to produce different kinds of beverages. The equipment has a compact structure, convenient operation and maintenance, and is equivalent to the advanced level of foreign counterparts.

Equipment characteristics

1) The water tank, syrup tank, and mixing tank of the mixing system are sealed. The upper parts of the three tanks are filled with CO2 gas or other clean gases during the working process to ensure that the mixed liquid will not be polluted by the atmosphere;

2) The mixing precision is high, and the mixing ratio can be adjusted;

3) CIP cleaning can be performed, and hot water or other chemical cleaning fluids can be used for cleaning and disinfection;

4) The whole set of equipment is installed on a stainless steel frame with adjustable legs;

5) It has a wide range of applications and can handle a variety of products such as carbonated beverages and fruit juice beverages;

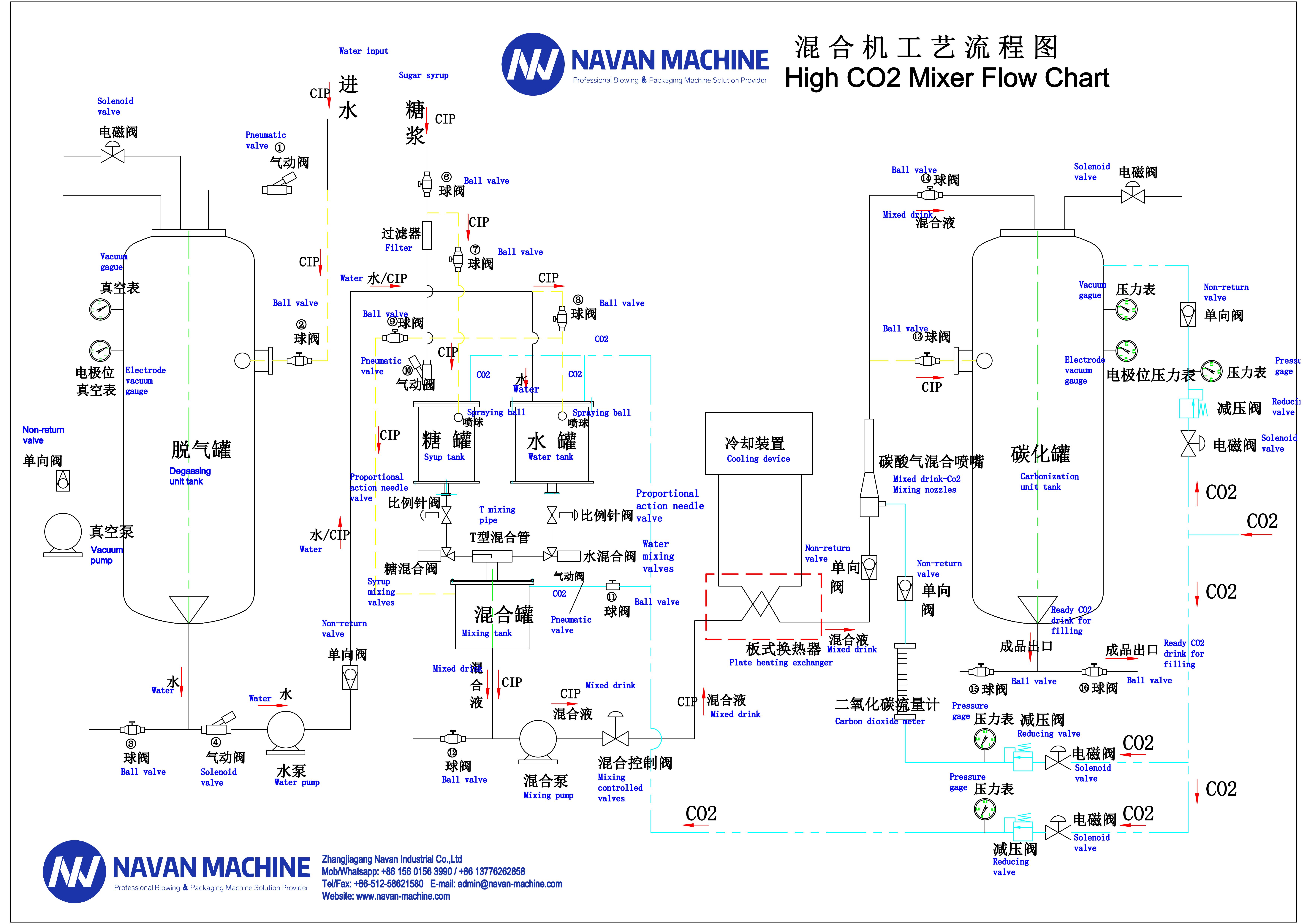

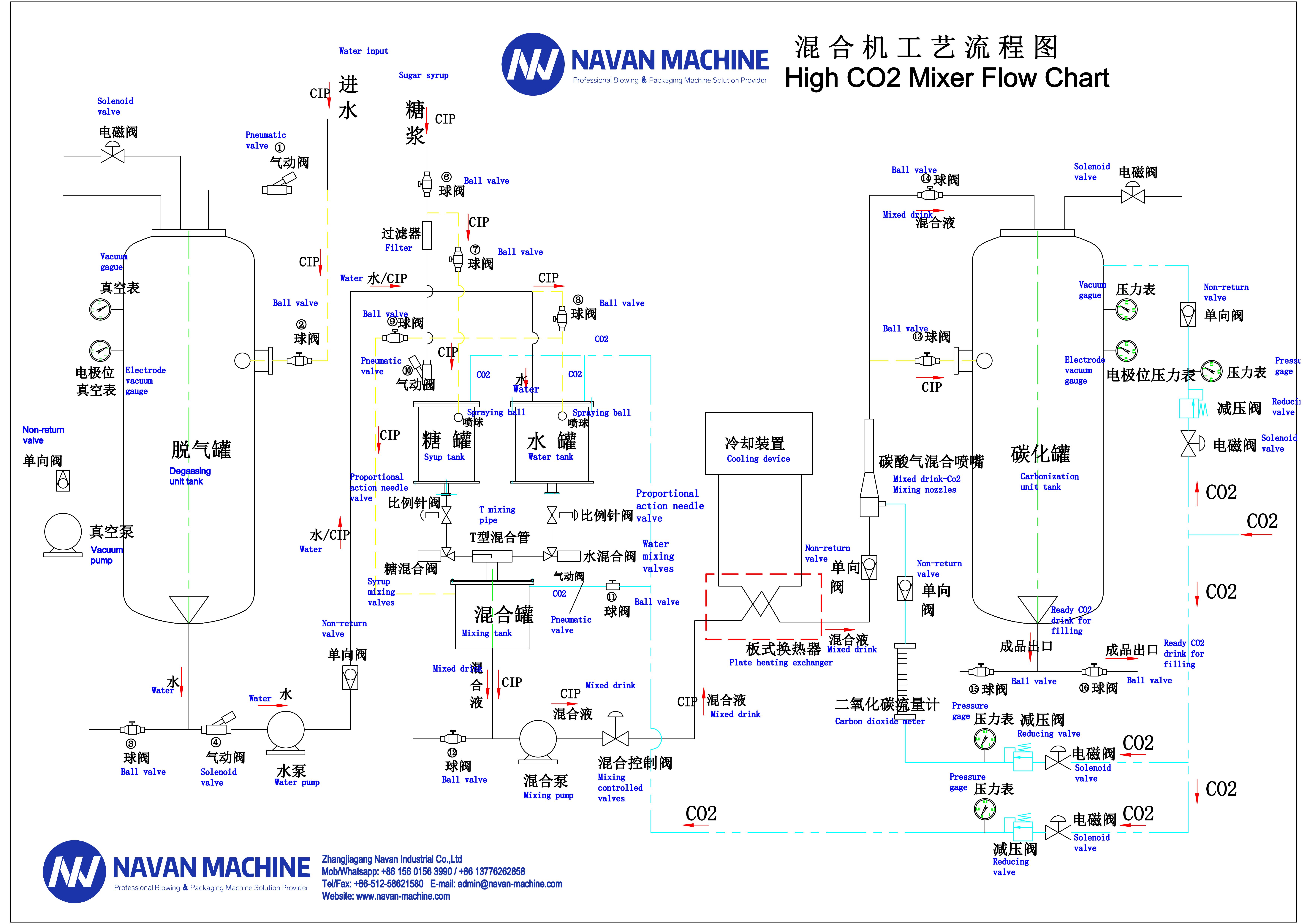

Technical Flow Charts

Main Components

Main Components

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

Pусский

Pусский Français

Français 简体中文

简体中文

Products Details

Products Details

Main Components

Main Components