New Upgraded 99.8% Industrial Drinking Water Treatment System Ultrafiltration Purification System Equipment

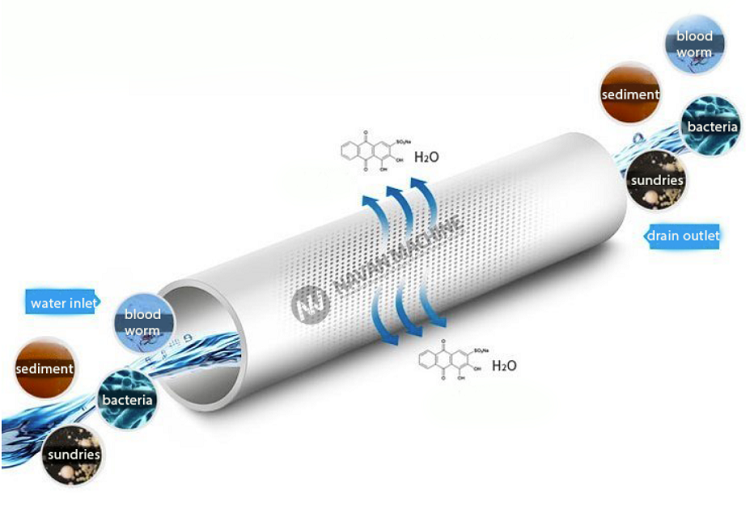

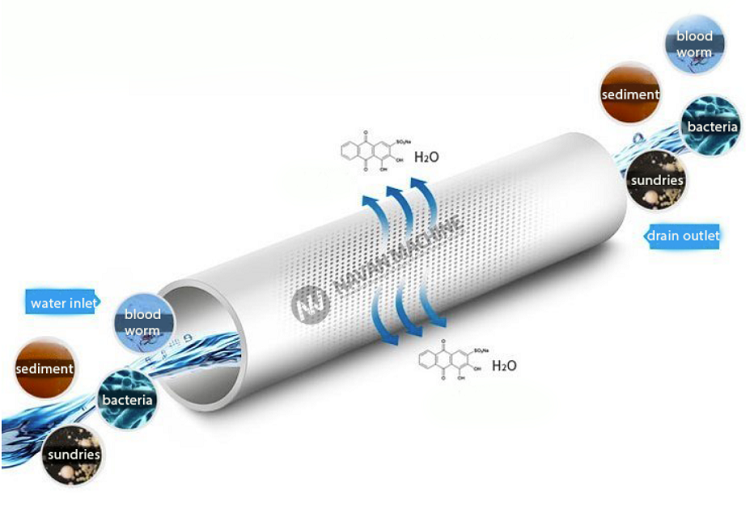

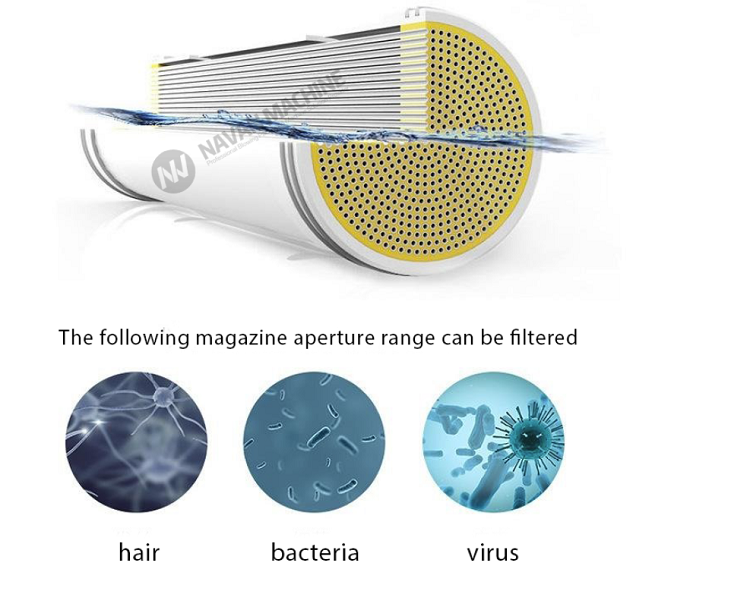

The hollow fiber ultrafiltration membrane only allows the solvent in the solution (such as water molecules), inorganic salts and small molecules of organic matter through, and the suspended matter in the solution, colloid, protein and microorganism and other macromolecular substances to intercept, so as to achieve the purpose of purification and separation.Ultrafiltration membranes are widely used in water treatment projects.Ultrafiltration technology plays an increasingly important role in reverse osmosis pretreatment, drinking water treatment, water reuse and other fields..

Ultrafiltration membrane separation technology.

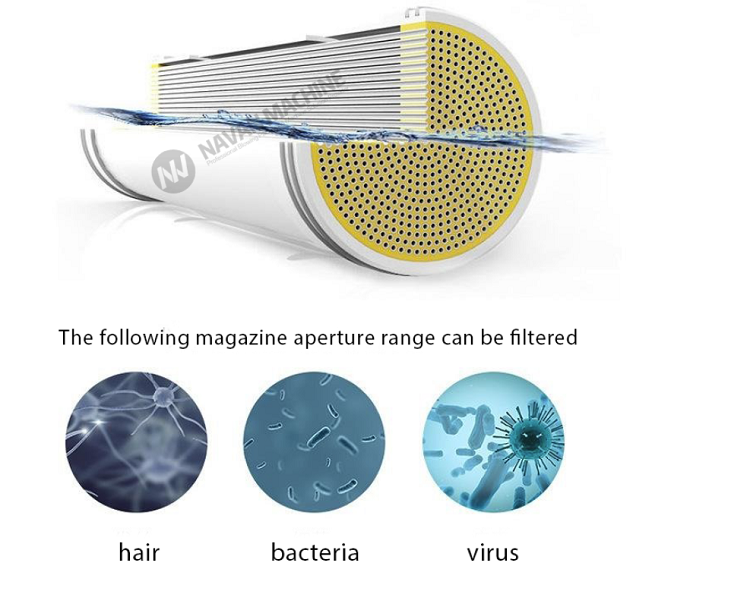

PVDF material, high transition precision, corrosion resistance, easy to wash.Screening is performed by a network of micropores on the membrane filament with a diameter of 0.03μm (about 1/100,000th of the diameter of a hair).Can completely intercept some harmful substances in the water, such as sediment, bacteria, red insects,macromolecular organic matter.

New core ultrafiltration membrane to create healthy water .

According to the raw water quality and installation environment design.

PVDF filament 0.03μm fine filtration.

Remove bacteria colloid and other harmful substances in water, and retain the beneficial minerals of human body.

Details about it.

Ultrafiltration membrane using polyvinylidene fluoride (PVDF) membrane filament material, resistant to cleaning, and through the unique hydrophilic treatment, can tolerate high concentration of oxidants for a long time, fully inhibit microbial reproduction;Adopt the external pressure structure with higher pollution intercepting capacity, with larger filtration area, allowing the use of air scrubbing process, so that the cleaning is more simple, more thorough, and more widely applied.

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details