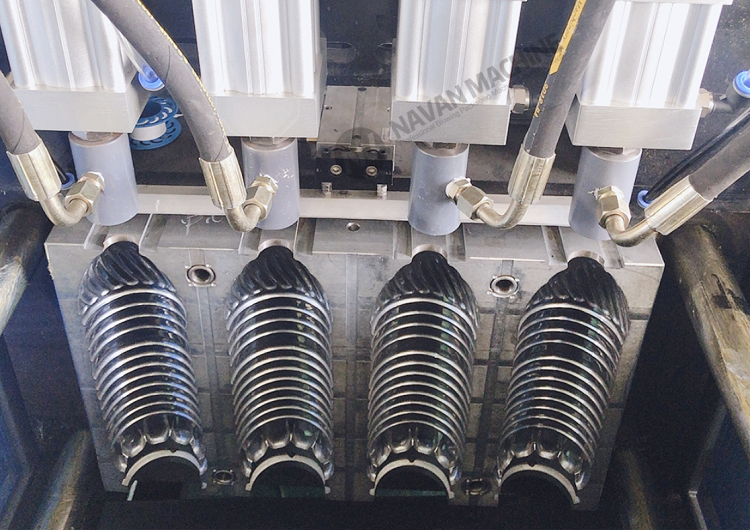

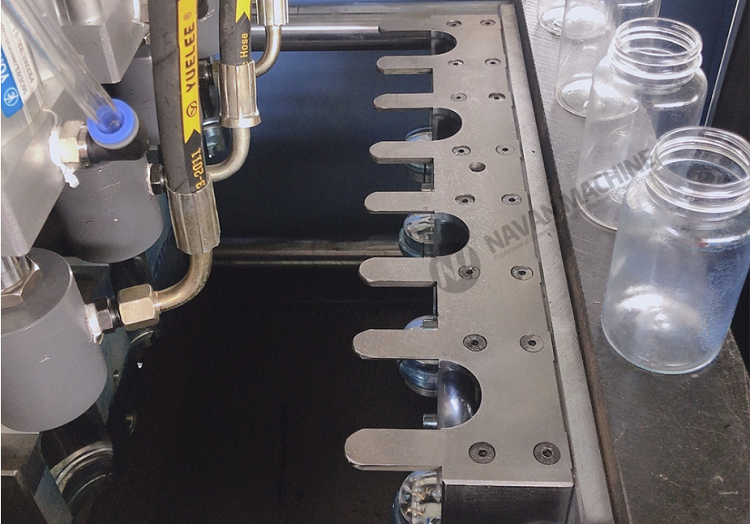

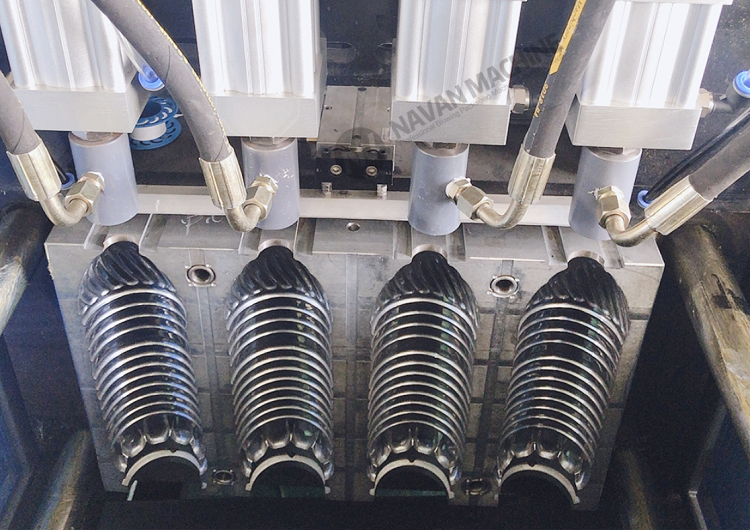

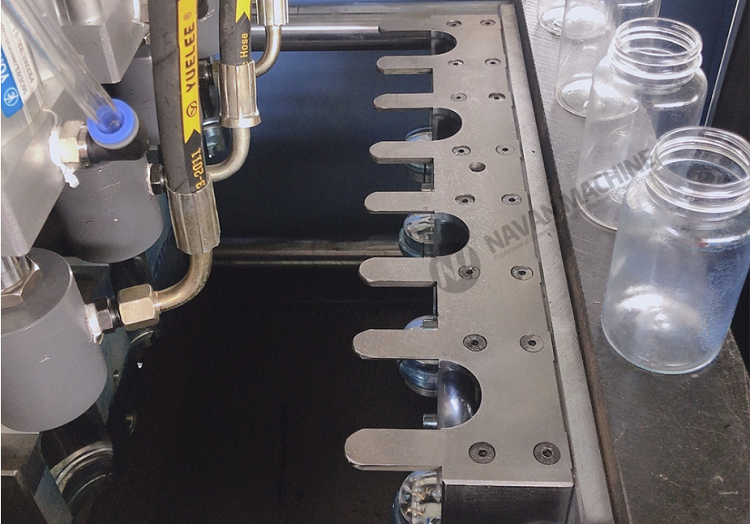

Semi Automatic 4 Cavity 1600-2000bph 0.2-2L Plastic Bottle Blowing Machine

Adopting double crankshaft crank arm connecting rod clamping system, stable clamping, fast running speed, far infrared rotary oven, uniform heating.

The air circuit system is divided into two parts: action and blowing. It performs actions and blows the needs of different air pressures, and also provides stable high pressure to blow special-shaped large-volume bottles.

Perfect function, economical investment.Small location, stable structure, saving space.

Simple operation, just one worker low power consumption, not easy to damage, adopts a new type double crank arm connecting rod to lock the mold, the structure support is stable, suitable for high-pressure bottle blowing system.

We can provide preforms and cap molds of different bottle types from 100ml to 2000ml too .

New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottle neck diameter.

Intelligent Human-Machine Interface.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

Pусский

Pусский Français

Français 简体中文

简体中文

Products Details

Products Details