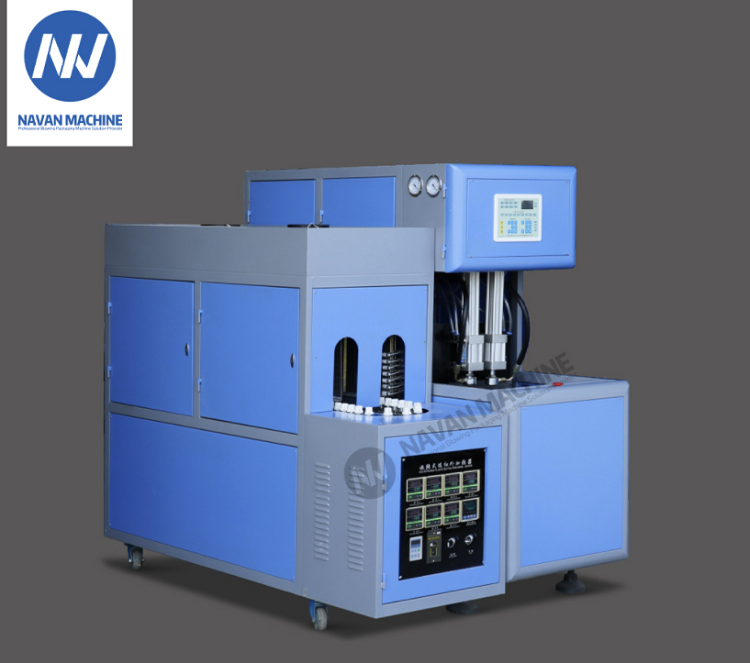

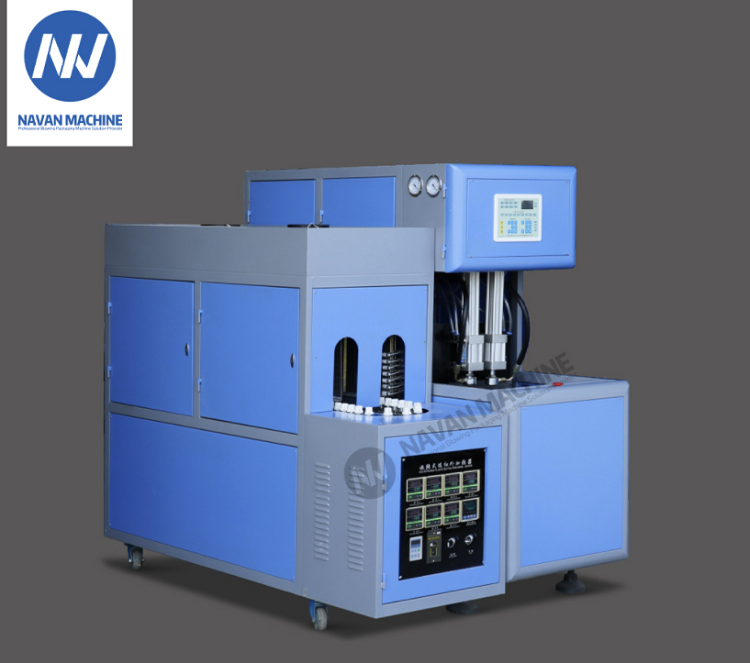

Semi Automatic Two Cavities 800-1000BPH 0.2 - 2.0L PET Bottle Stretch Blow Molding Machine

The semi-automatic blow molding machine meets CE standards. Controlled by a microcomputer, the technical parameters involved can be controlled more accurately. The operation is simple and safe, only one person is required and no special training is required. This machine can blow carbonated beverage bottles, mineral water bottles, cosmetic bottles, pesticide bottles and jars, etc. Adopting double-boom five-point four-rod clamping structure, sprocket mold adjustment, high-hardness cast iron or steel plate, high mold clamping force, wear resistance, tight and fine clamping seam. Adopt advanced touch screen control system, simple, fast and stable operation.Use adjustable far-infrared heating tube, heating temperature is constant, easy to debug.Independent temperature control to ensure that the preform baking reaches the ideal state.Easy installation, one person operation, no special training, simple and convenient.

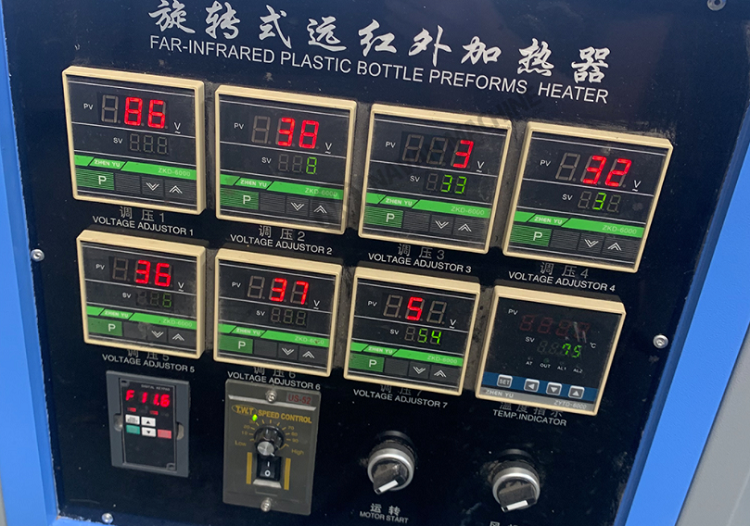

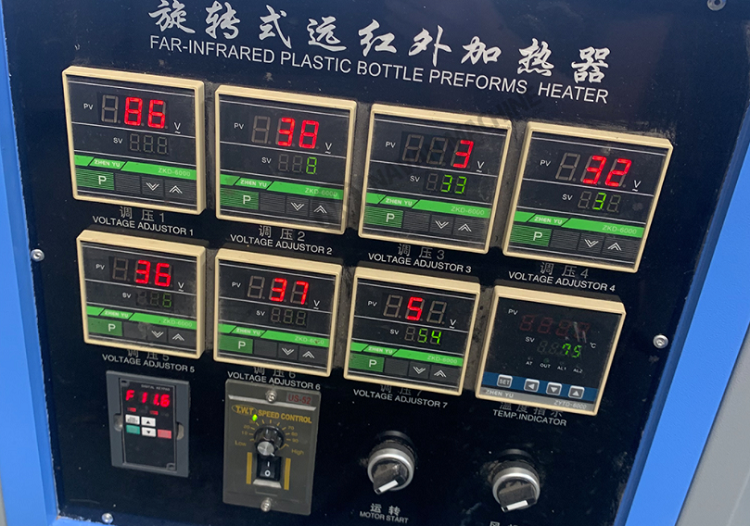

New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottle neck diameter.

Intelligent Human-Machine Interface.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

Navan Services Online

Navan Services Online Options & Upgrades

Options & Upgrades Spare Parts

Spare Parts

简体中文

简体中文 Pусский

Pусский

Products Details

Products Details